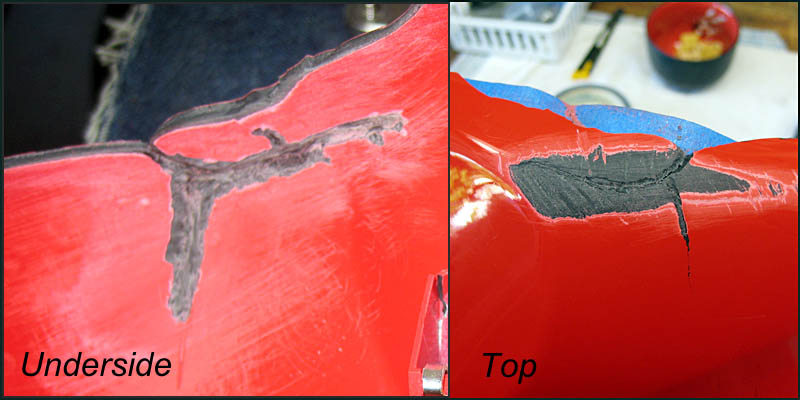

I'll start with the fuel tank cover. There are a few cracks that join each other and in order for the plastic weld to adhere to the pieces there needs to be a good surface for it to grab onto. The cracks here are very jagged so I took a dremel to the cracks to create a nice groove for the adhesive to bond to. This allows more adhesive to fill the void and provide a stronger grip on the adjoining pieces.

First I put some tape along the outside of the cover so that the pieces would all be flush and even while I used the dremel to work the cracks.

If I just left the surfaces flush then sanding the area would cause all of the plastic weld to be removed in order to get a smooth surface. We want a good amount of plastic weld in there so making a valley along the crack is ideal.